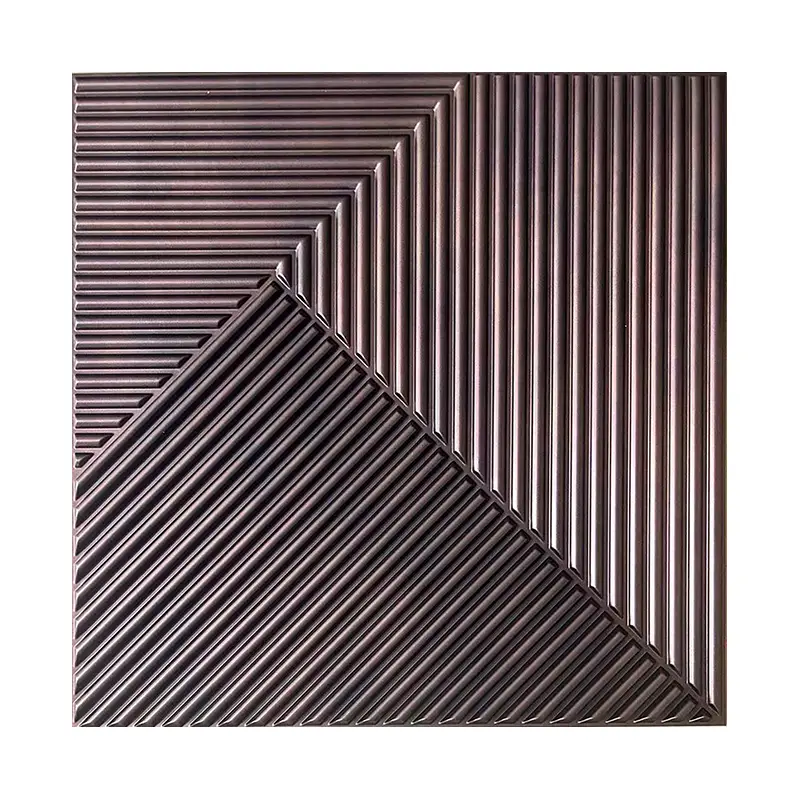

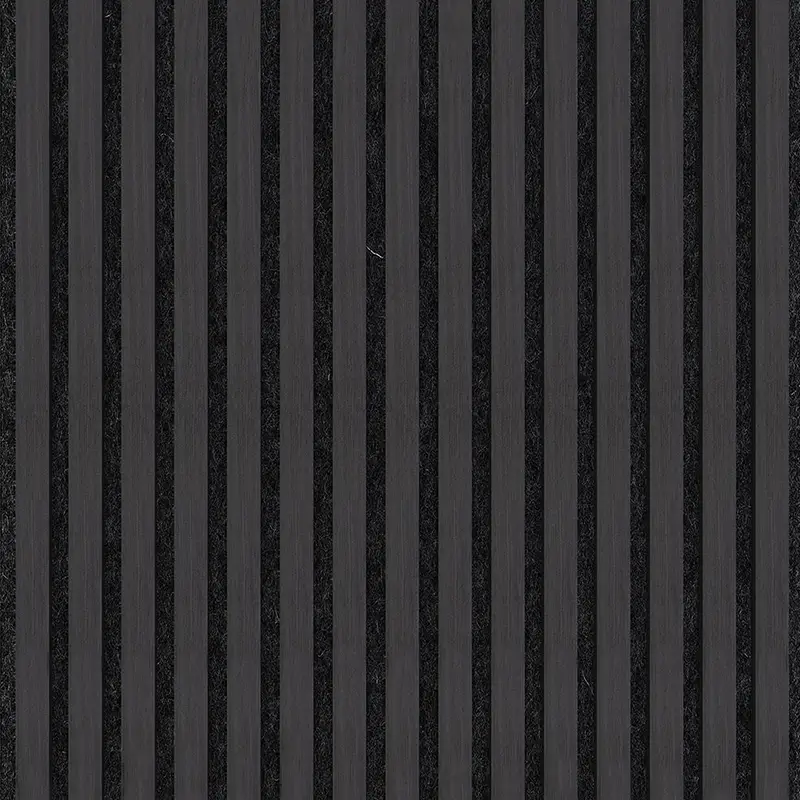

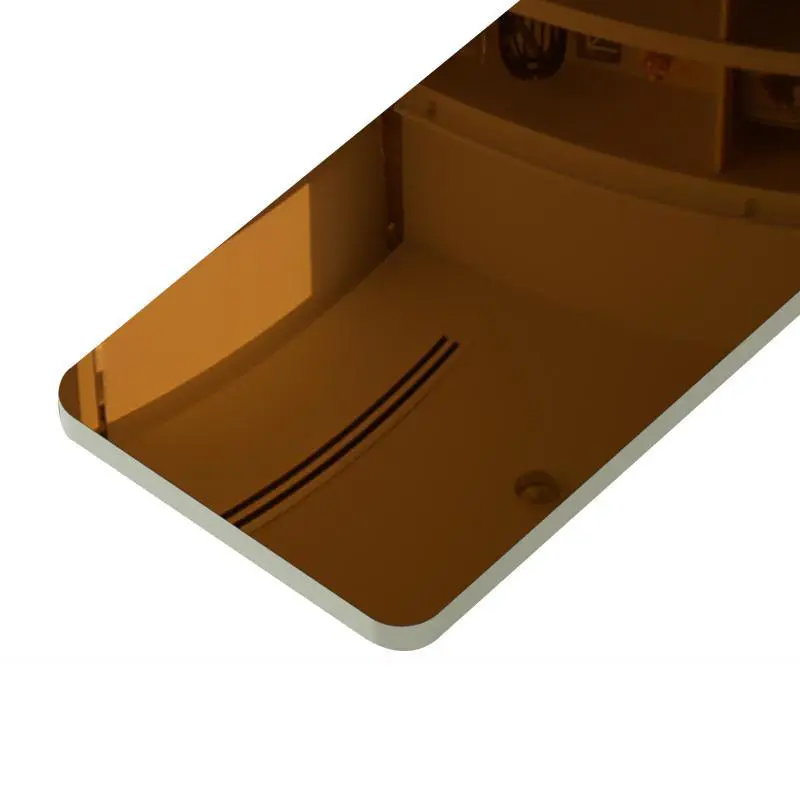

Chocolate Brown Acoustic Panel

Category:

MDF Slat Acoustic Wall Panel

Keyword:

Chocolate Brown Acoustic Panel

Still deciding? Get samples first, Contact US !

Description

Material Composition

Medium Density Fiberboard (MDF): is the main substrate, made of wood fiber or other plant fiber and synthetic resin under high temperature and high pressure, it has the advantages of uniform material, compact structure, high strength, easy to process, etc. It can provide stable support and good durability for the wall panels.

Sound-absorbing materials: usually with polyester fiber sound-absorbing panels, acoustic felt, etc. as sound-absorbing layer. These materials have good sound-absorbing properties and can effectively absorb and reflect sound waves to reduce noise pollution.

Product Features

Excellent acoustic performance: the unique slat design combined with sound-absorbing materials can effectively absorb and scatter sound waves, reduce sound reflection and echo, improve the acoustic quality of the space and create a quiet and comfortable environment.

Highly decorative: Different veneer veneers, paint colors, slat widths and spacing can be selected to achieve diversified appearance effects and add unique decorative styles to the space.

Convenient installation: Generally adopting modular design, the slats are spliced together through specific connection methods, which makes the installation process simple and fast, and can be directly fixed on the wall or ceiling without complicated construction techniques.

Environmental protection and durability: the selected MDF panels and sound-absorbing materials usually meet the relevant environmental standards, non-toxic and odorless, harmless to human health and the environment.

Application Areas

Commercial space: such as shopping malls, hotels, restaurants, bars, etc., can be used for wall and ceiling decoration and sound absorption.

Office space: office, conference room, negotiation room and other places using MDF slatted sound-absorbing wall panels, can effectively reduce noise interference, improve work efficiency.

Home space: installing MDF slat acoustic wall panels in living room, bedroom, study room and other areas can not only absorb va

Chocolate Brown Acoustic Panel

Category:

MDF Slat Acoustic Wall Panel

Keyword:

Chocolate Brown Acoustic Panel

Still deciding? Get samples first, Contact US !

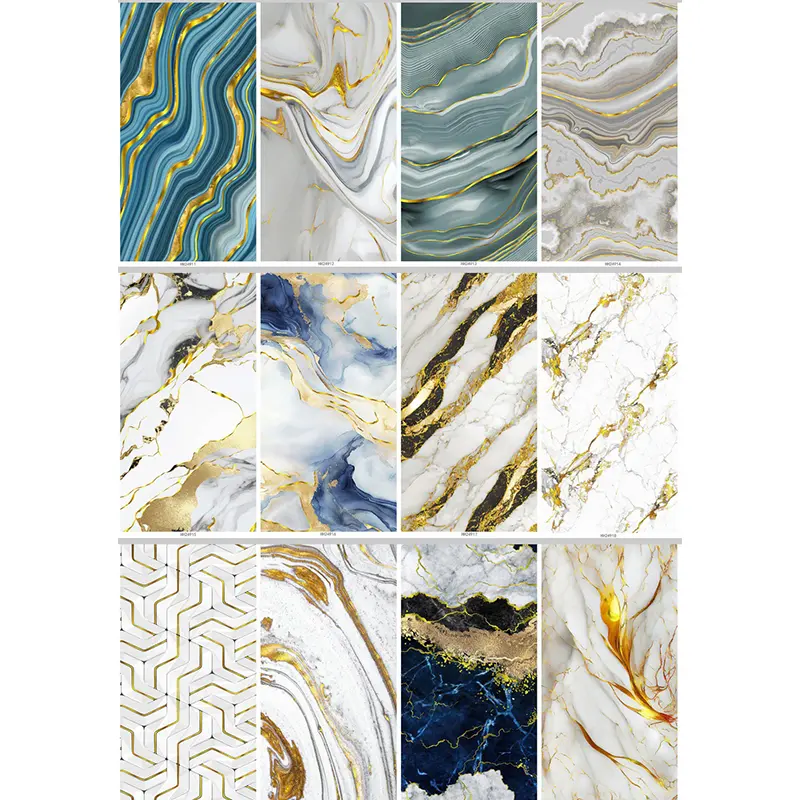

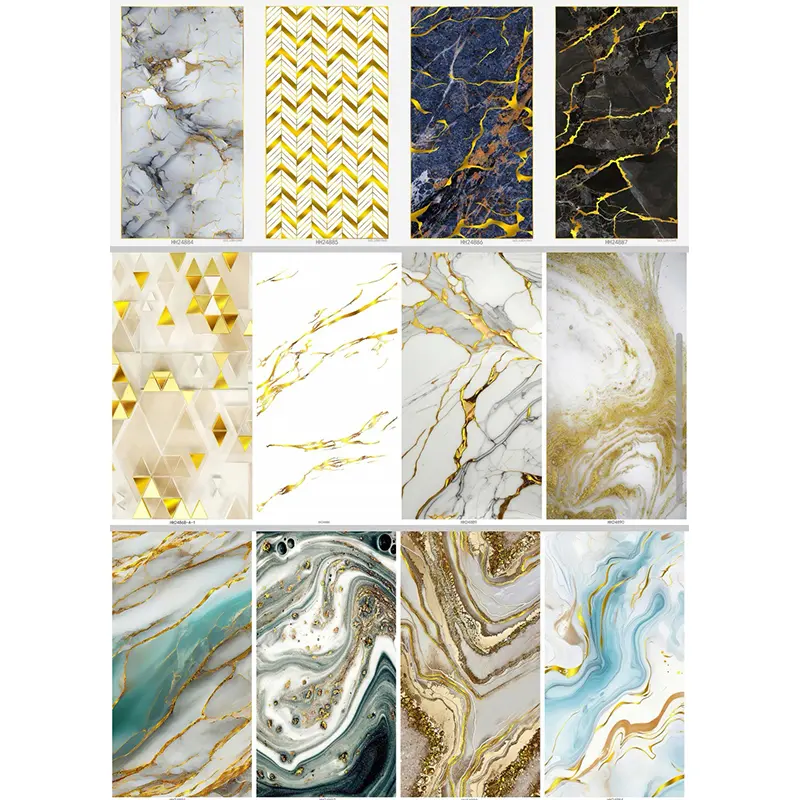

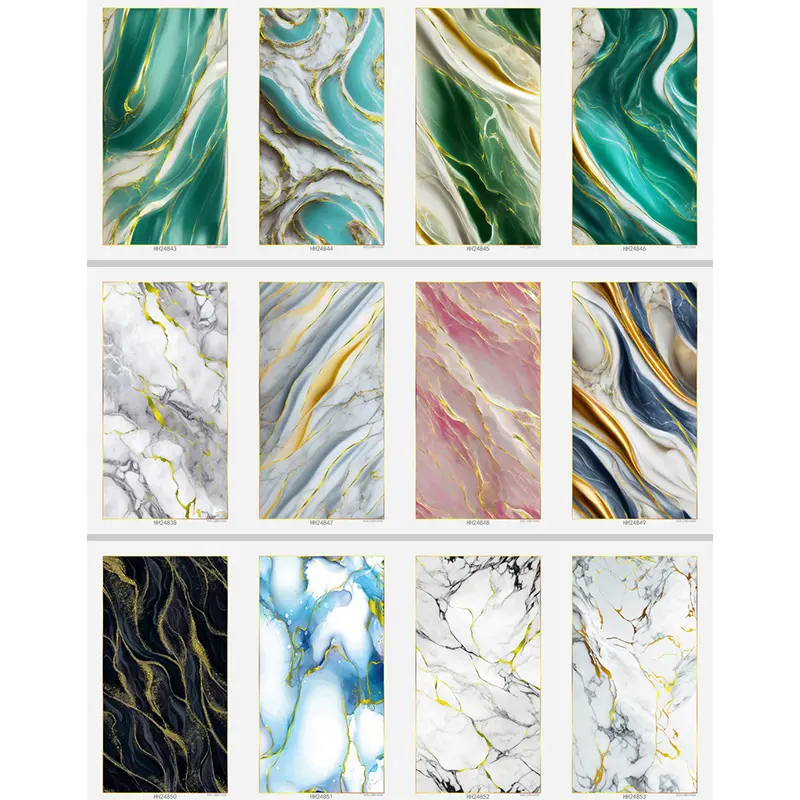

Related Products

Indoor Materials

MDF Slat Acoustic Wall Panel

-

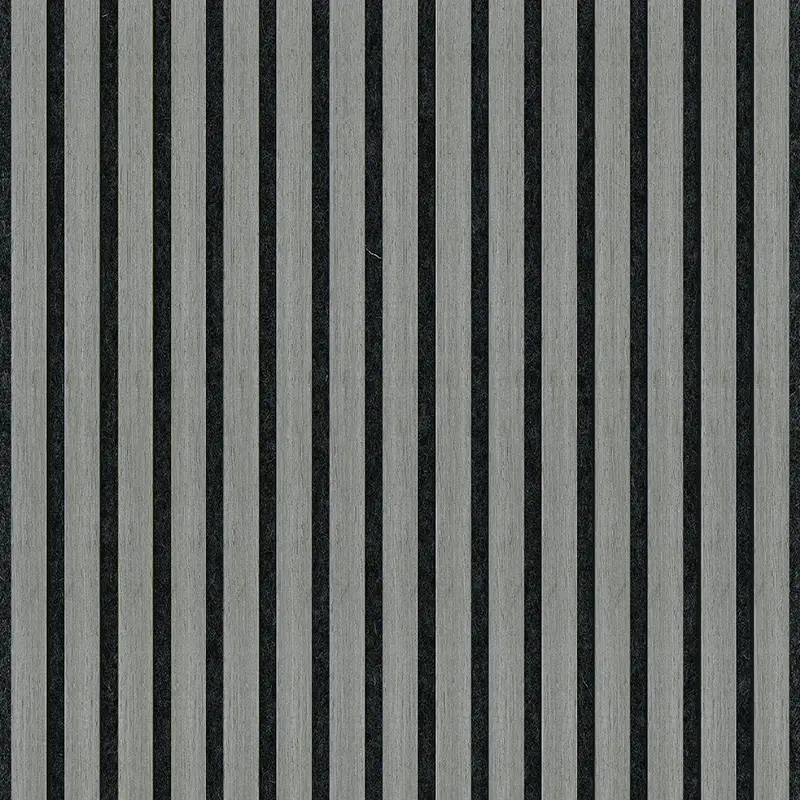

Ash Grey Acoustic Panel

-

Black Oak Acoustic Panel

-

Chocolate Brown Acoustic Panel

-

Grey Oak Acoustic Panel

-

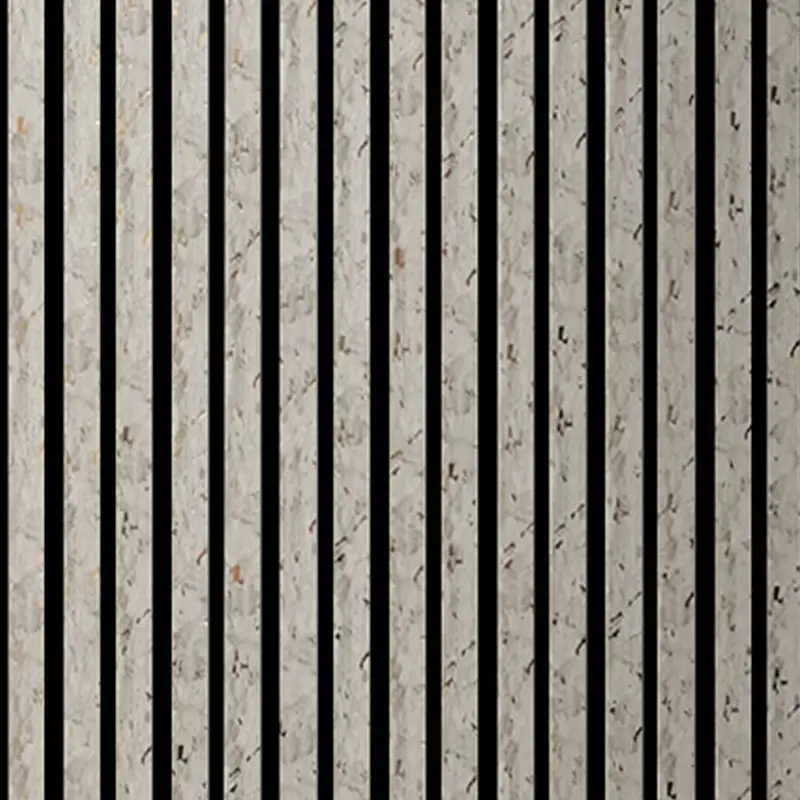

Light Walnut Acoustic Panel

-

Natural Oak Acoustic Panel

-

Beige Gold Dot Acoustic Panel

-

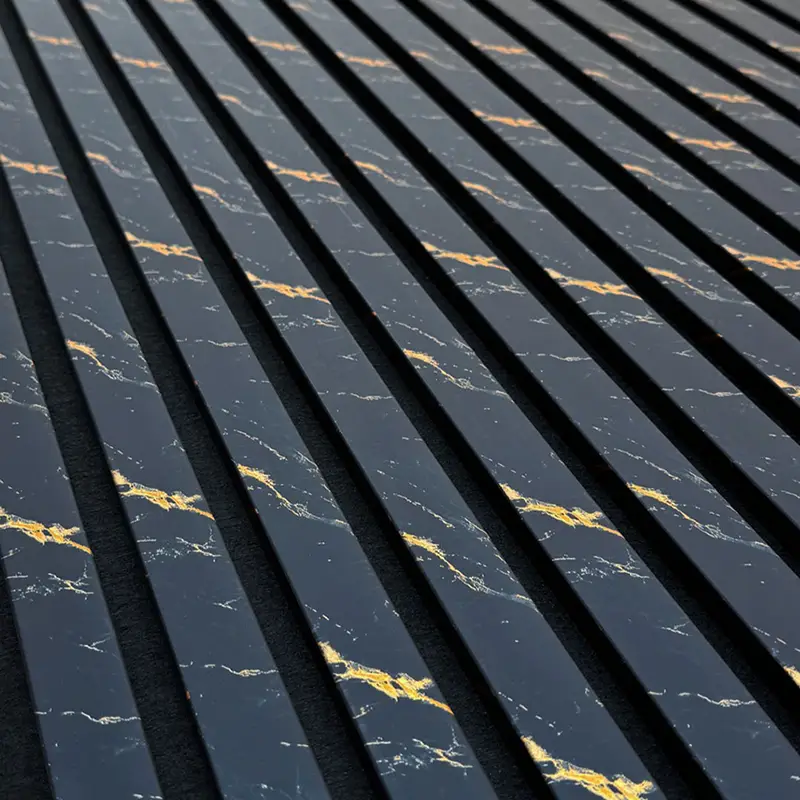

Black Gold Dot Acoustic Panel

-

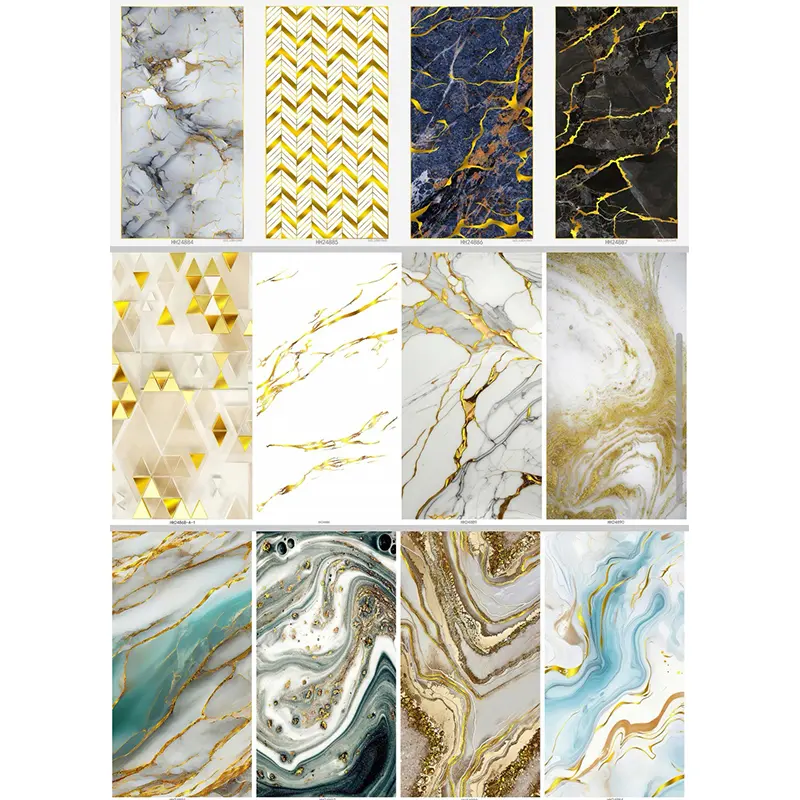

Black Gold Marble Acoustic Panel

-

Black Gold Vein Acoustic Panel

-

White Gold Marble Acoustic Panel

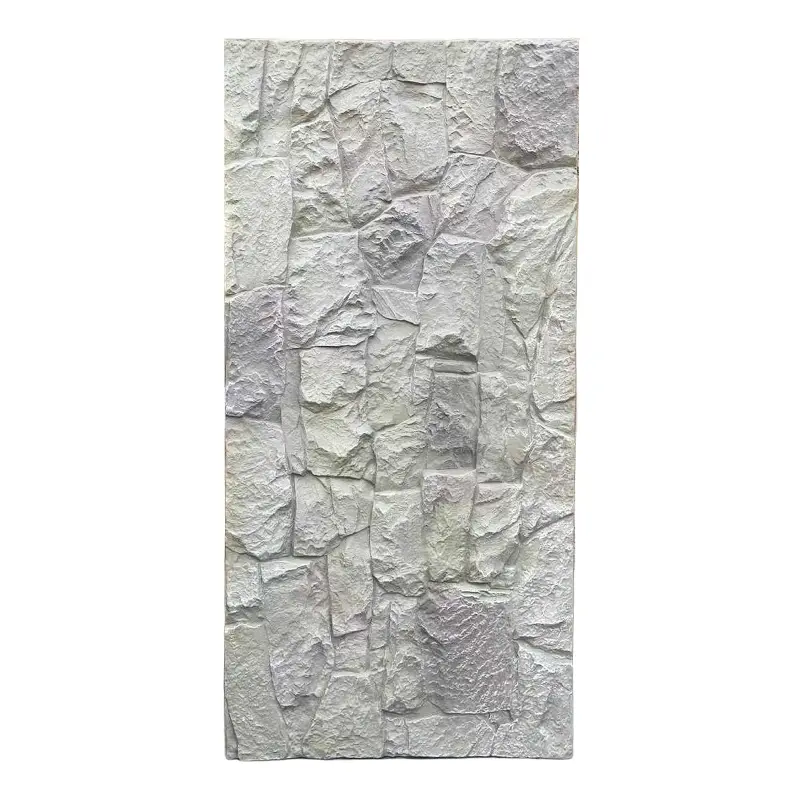

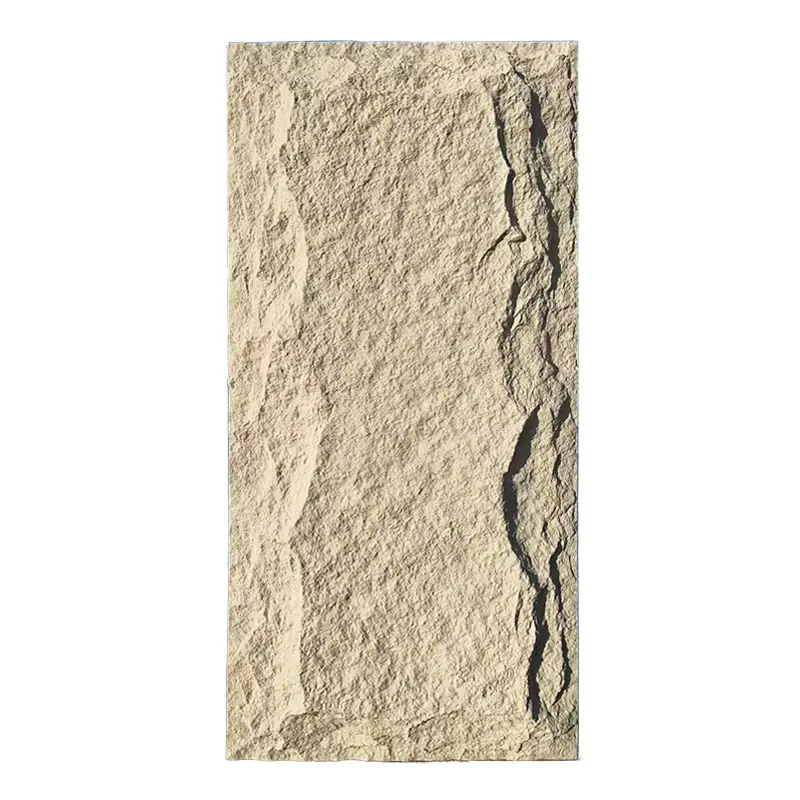

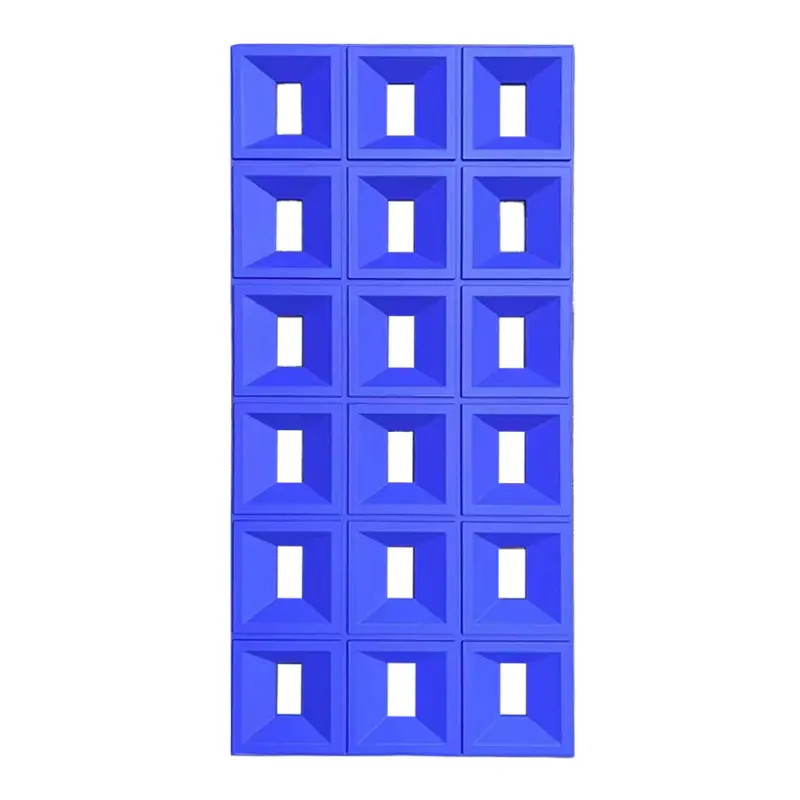

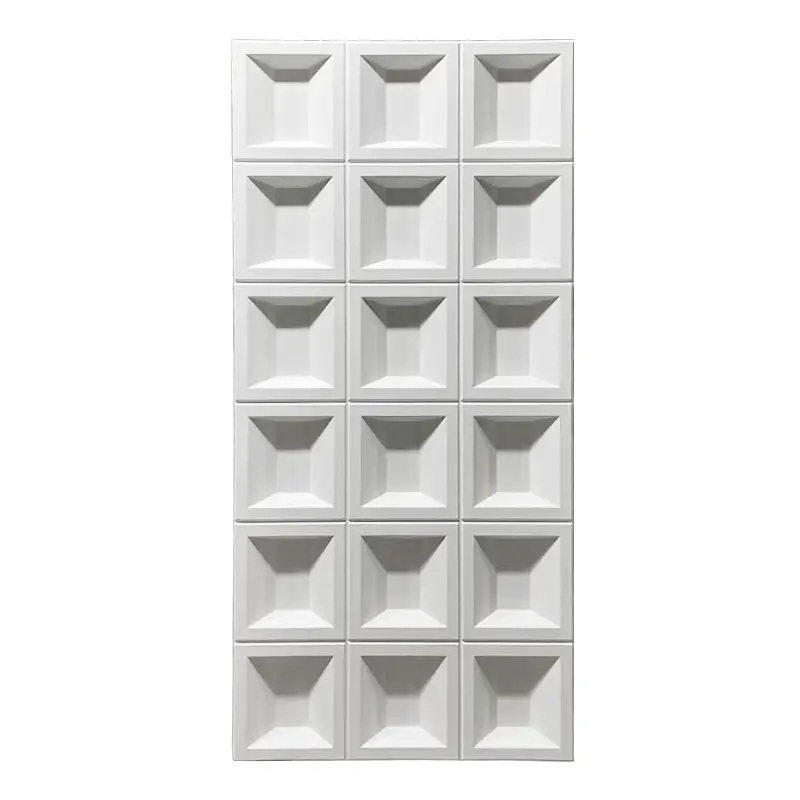

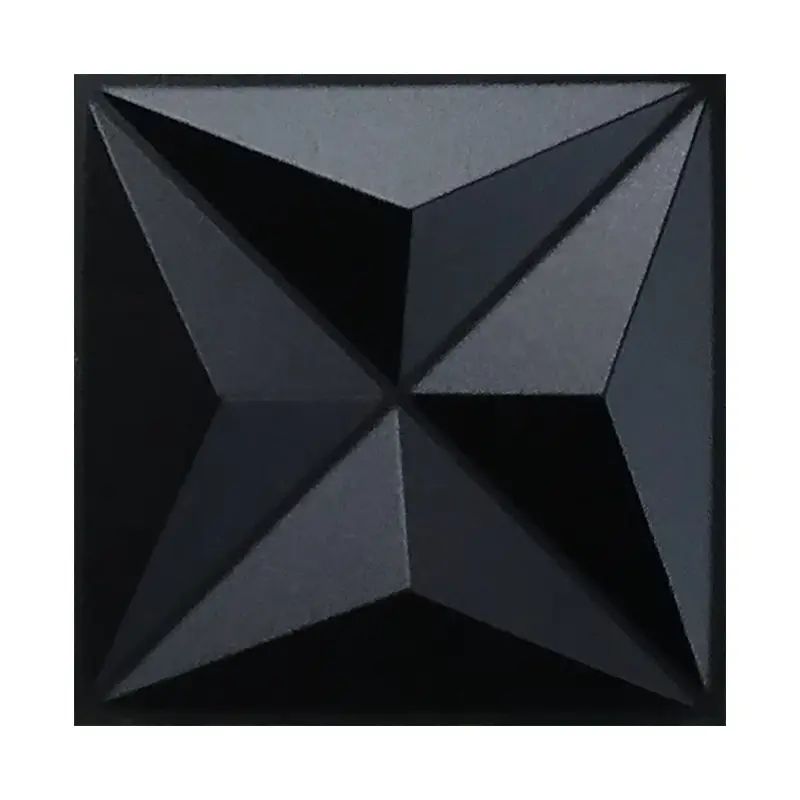

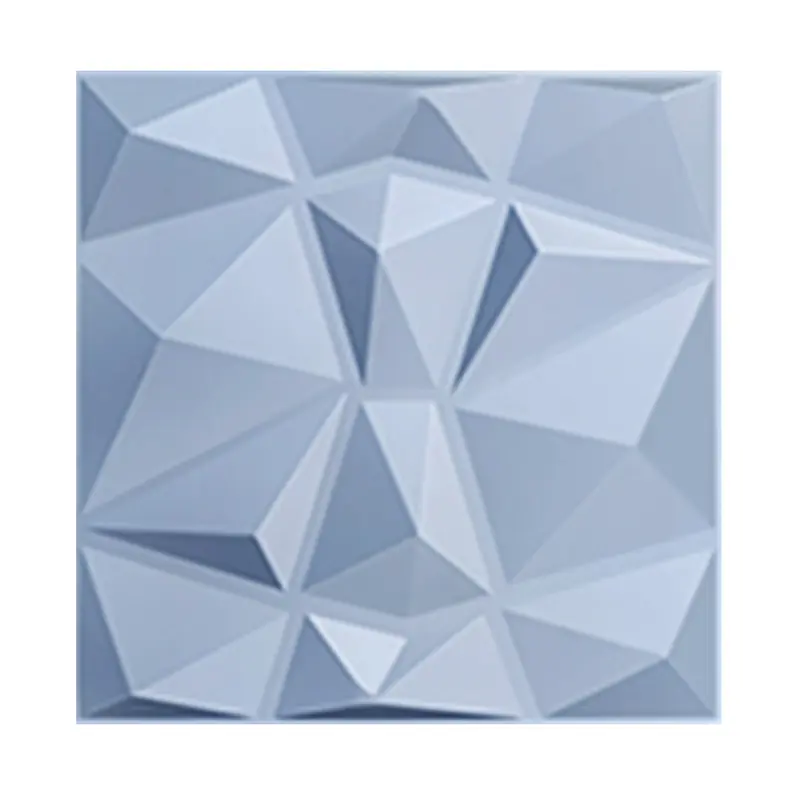

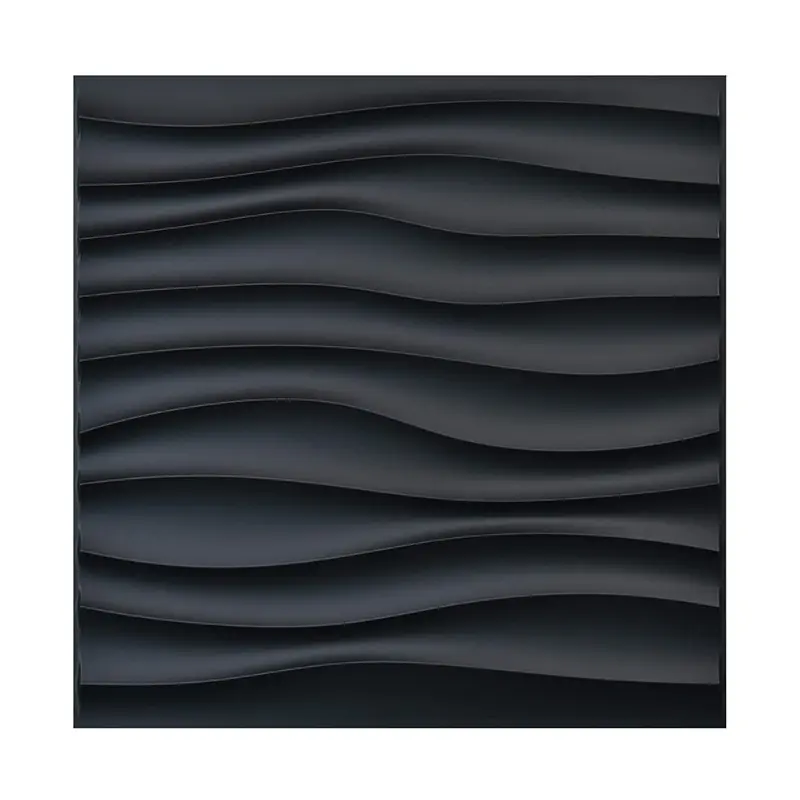

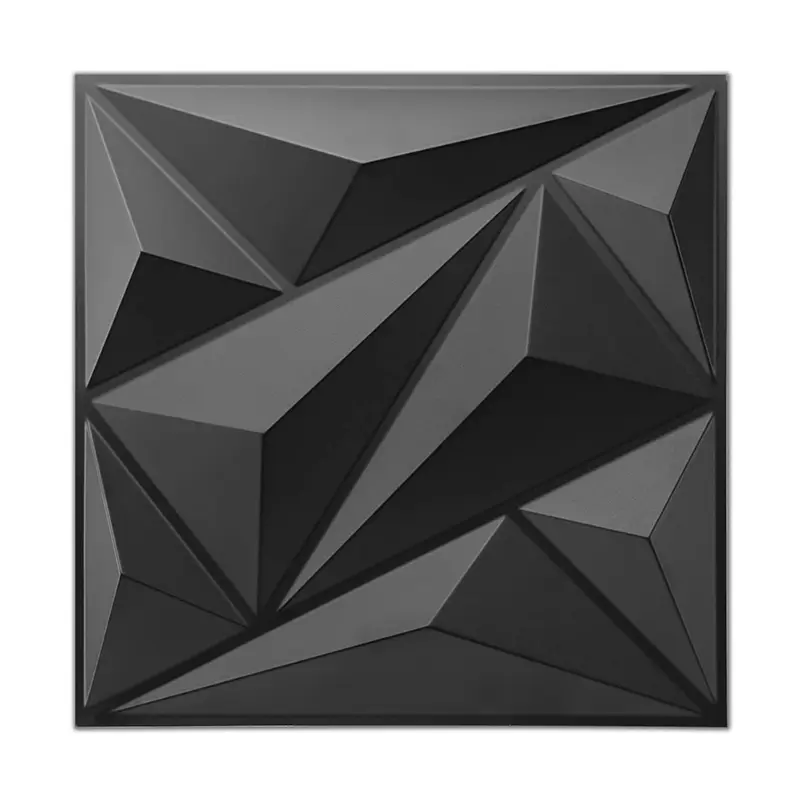

PU 3D Wall Panel

PVC 3D Wall Panel

PVC Marble Wall Panel

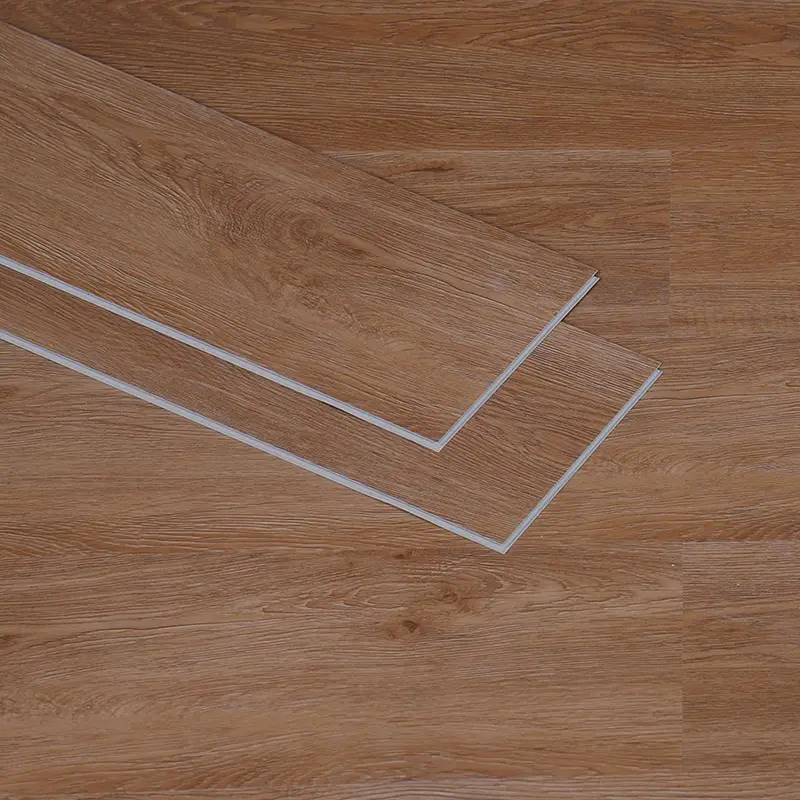

SPC Flooring

WPC Bamboo Fiber Bamboo Charcoal Co-extrusion Panel

-

WPC Bamboo Fiber Bamboo Charcoal Coextrusion Panel(metalized pattern)

-

WPC Bamboo Fiber Bamboo Charcoal Coextrusion Panel(mirror effect)

-

WPC Bamboo Fiber Bamboo Charcoal Coextrusion Panel(wood pattern)

-

WPC Bamboo Fiber Bamboo Charcoal Coextrusion Panel(ripple pattern)

-

WPC Bamboo Fiber Bamboo Charcoal Coextrusion Panel(marble pattern)

WPC Ceiling Tube

WPC Interior Fluted Wall Panel

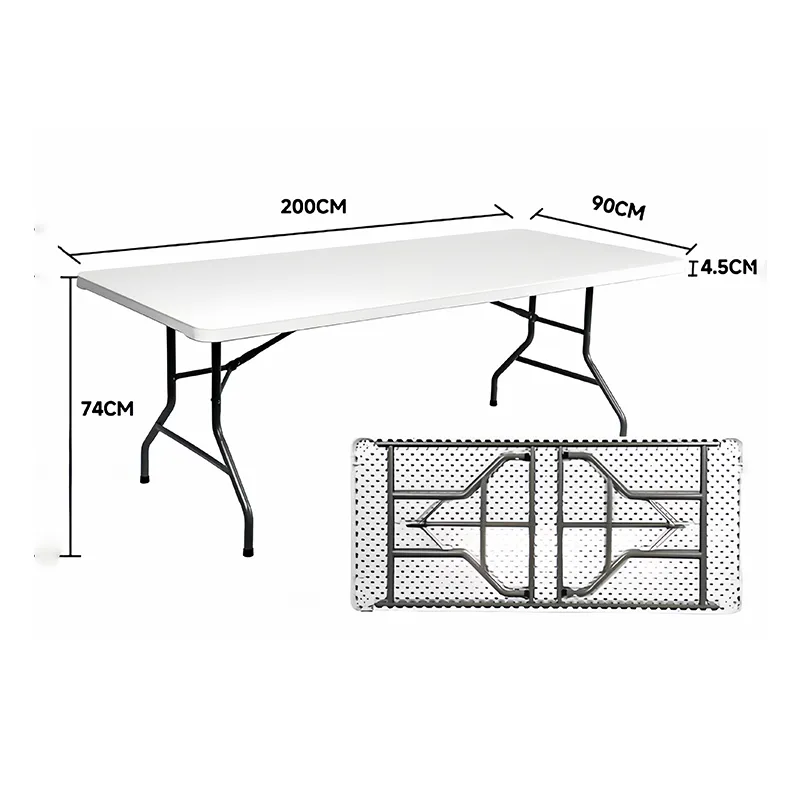

Fold-in Table and Chair

Outdoor Materials

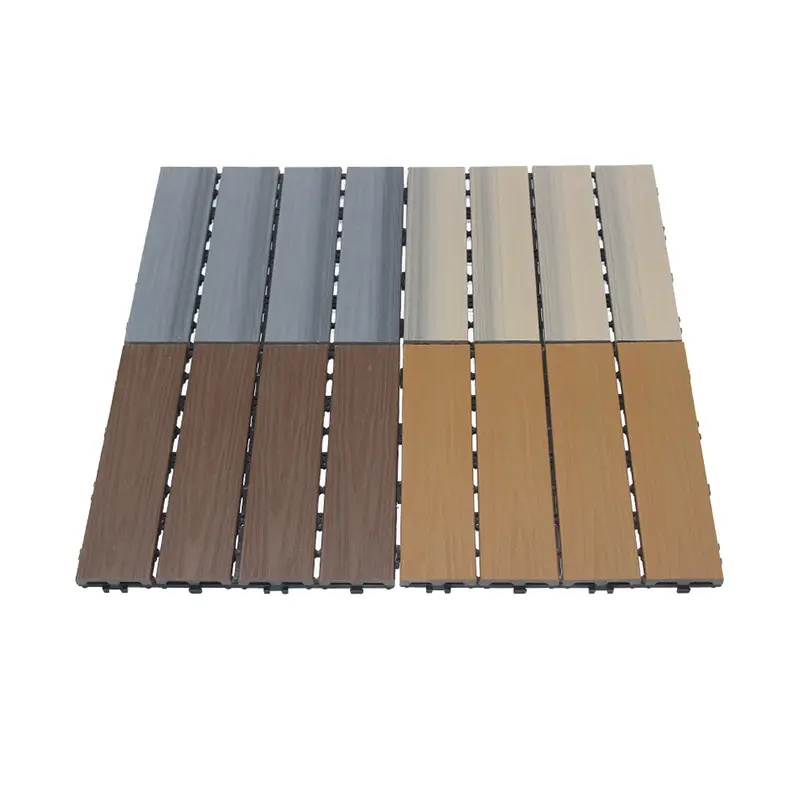

WPC Decking

WPC Exterior Fluted Wall Panel

WPC Outdoor Wall Cladding

Plastic Raw Materials

-

ABS Resin

Good impact resistance: even in low-temperature environments (such as - 40 ℃), can still maintain a certain degree of toughness, not easy to embrittle, suitable for the production of parts that need to resist collision (such as luggage, toys).

-

Polycarbonate Resin

Polycarbonate Resin is a high-performance thermoplastic engineering plastics, known for its excellent impact strength, light transmission, heat resistance and dimensional stability, widely used in electronics, automotive, construction, medical and other fields.

-

PC/ABS Resin

PC/ABS resin is a polycarbonate (PC) and acrylonitrile - butadiene - styrene copolymer (ABS) through the blending and modification of alloy materials, both the advantages of the two resins, while making up for their respective shortcomings, is currently one of the most widely used engineering plastics alloy.

-

Polypropylene Resin(PP)

Polypropylene Resin (PP), a thermoplastic polymer made by polymerizing acrylic monomers, is one of the most produced and widely used plastics in the world.

-

Polyvinyl Chloride Resin(PVC)

Polyvinyl chloride (PVC) resin is a common thermoplastic synthetic resin made by polymerization of Vinyl Chloride Monomer (VCM).

-

HDPE 100s

HDPE is a highly crystalline non-polar thermoplastic resin produced through the copolymerization of ethylene and a small amount of a-olefin monomer.

-

Polyethylene Wax (PE Wax)

Polyethylene Wax (PE Wax), also known as polymer wax, is a low molecular weight polyethylene material renowned for its exceptional cold resistance, heat resistance, chemical stability, and abrasion resistance.

-

Fischer Tropsch Wax (FT Wax)

Fischer Tropsch Wax (FT Wax) is a synthetic hydrocarbon wax produced via the Fischer-Tropsch process from synthesis gas (syngas) or natural gas. It primarily utilizes cost-effective coal-chemical raw materials for iron-based or cobalt-based synthesis.